Nanotextures solve a historic problem

What does the pipework in a modern desalination plant and a 1 BC Roman cooking pot have in common? You would think nothing at first.

But archaeological digs uncovering the history of humanity throughout the centuries have shown us that ancient civilizations lived with a dilemma we are still trying to resolve: the accumulation of scale left by water on metal objects.

This same handicap, which has persisted since man’s first use of technology, will soon be a thing of the past, thanks to researchers from Massachusetts Institute of Technology (MIT). They have spent the past two years developing coatings for metal surfaces that will avoid accumulation of the deposits left by water.

“Ancient civilizations lived with a dilemma we are still trying to resolve”

How are such deposits accumulated?

When water cools, or evaporates, its capacity to dissolve is reduced and the mineral salts that have not dissolved in it tend to separate from the liquid and stick to walls and surfaces. These scales accumulate and with the passage of time cause inefficiency in pipes due to flow loss, changes in internal pressure and other negative factors.

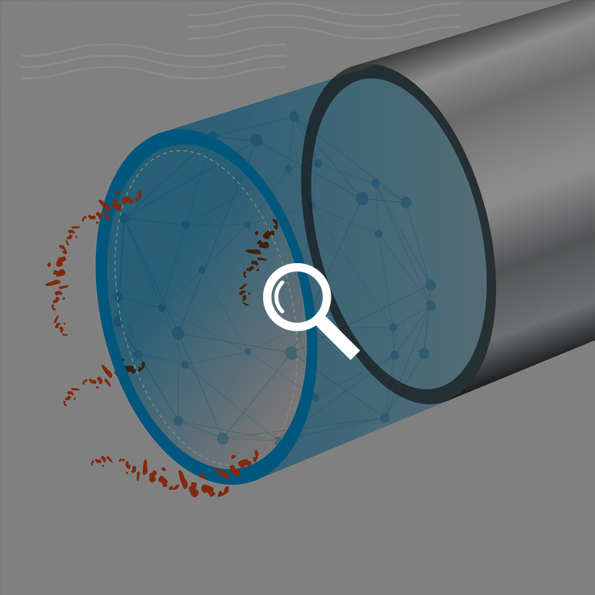

The solution being developed: nanotextured surfaces

The work of the MIT scientists is based on the development of nanoscale texturing for the inside of pipes, which is then coated with a lubricating liquid. The lubricant remains captive between the nanotextured layers and capillary action prevents it from escaping so that the minerals the water leaves in its wake slide away and fail to accumulate.

“This innovation would save up to 10 times the accumulation of waste, increasing the efficiency of water treatment plants”

Benefits of nanotextured surfaces

Thanks to this innovation, the accumulation of residue has been reduced up to tenfold, increasing efficiency in water treatment plants, for example. It has also been responsible for removing barriers to refrigeration and condensation in heat exchangers.

Meanwhile, as a result, maintenance is becoming cheaper at gas and oil facilities, through more homogeneous flows, and environmental impact minimized, since a small quantity of lubricant, according to MIT, guarantees the optimum operation of the pipelines during the useful life of materials.

The solution could mean an end to a problem that humans have lived with for hundreds of years.