A New Technique Paves the Way for 3D-Printed 5G and 6G Antennas

On this page, we have spoken on multiple occasions about the potential of 5G, which is quickly becoming a standard in developed countries. The benefits are undeniable, from the reduced latency that will support driverless vehicles to the coverage of millions of devices per square mile driving the Internet of Things. However, not everyone benefits at the same rate. Getting the most disadvantaged and remote areas to participate in these advances is the goal of a project at the University of Sheffield in the United Kingdom.

What are the main 5G infrastructures and bands?

The deployment of 5G networks requires substantial investments in radio spectrum and hardware in the form of antennas. So much so that implementation is gradual, with two types of architecture:

- Non-Stand Alone Architecture (NSA), which takes advantage of the existing 4G infrastructure, although with limited functionalities. Thus, they have a latency of 15 ms and speeds of up to 2 Gbps.

- Stand Alone (SA) architecture, which will enable the full potential of 5G to be realized, including latencies of 1 ms and transmission speeds of up to 20 Gbps.

Besides the hardware side of things, 5G antennas are also classified by the bands in which they operate.

- Sub-6, which operate below 6 GHz, typically between the 3.4 GHz and 3.8 GHz frequencies. These are used in urban environments, as they suffer less interference from physical or climatic obstacles.

- mmWave or millimeter wave, which operate between 24 GHz and 100 GHz. These frequencies offer higher speed and lower latency but require a more significant number of repeaters to compensate for the lack of penetration. This is the type of frequency that will be used as a priority in 5G SA infrastructures.

3D Printing of 5G and 6G Antennas

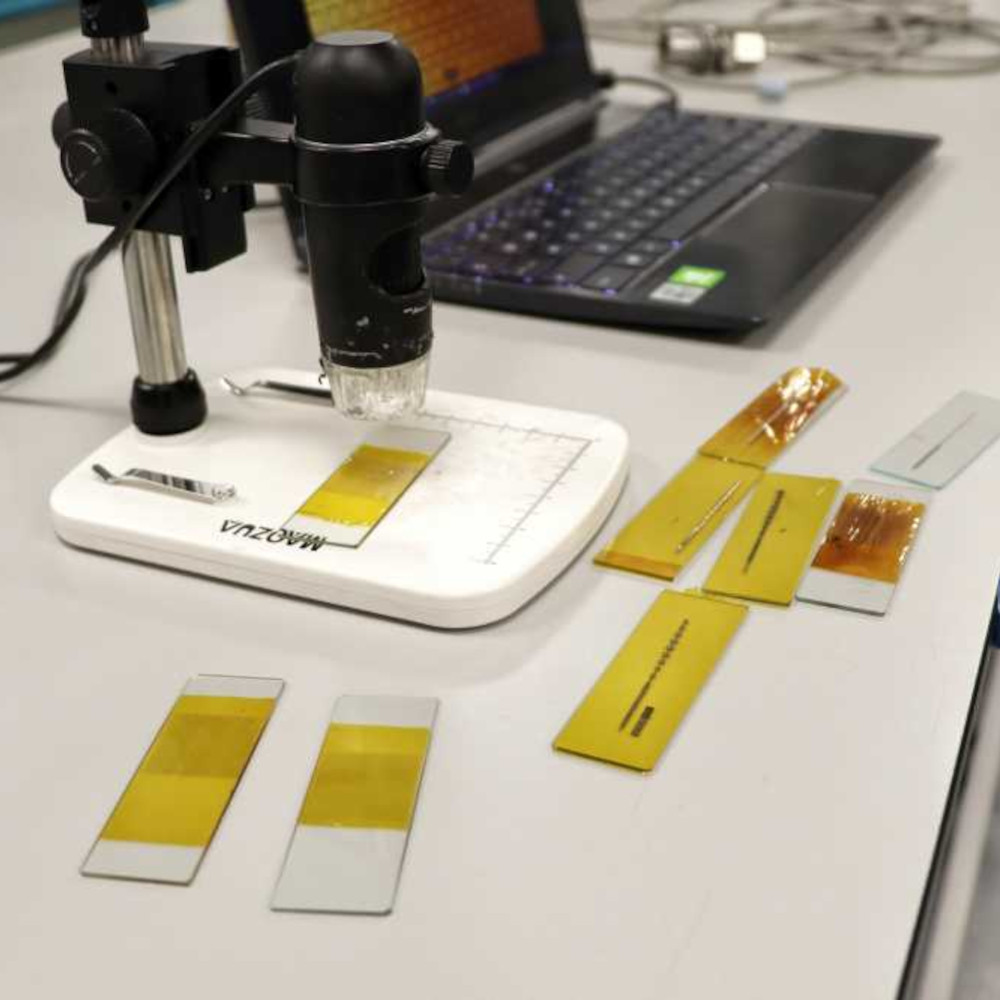

As seen, mmWave antennas will be crucial to take full advantage of this technology. And those are the 3D-printed devices developed by the Department of Electronic and Electrical Engineering at the University of Sheffield. The British university has just demonstrated the feasibility of 3D-printed 5G and 6G antennas, radically reducing cost and production times.

Thus, the new technique uses silver nanoparticles to print antennas in a few hours at the cost of just a few dollars, all without sacrificing functionality. In comparison, traditional 5G mmWave antennas can cost hundreds of euros, with much slower manufacturing.

The developers point out that the new design will make it possible to produce large-scale, low-cost antennas to reach remote areas and provide coverage quickly and efficiently. Criteria such as miniaturization, speed of manufacture, low cost, and ease of installation define the usefulness of this type of technology in developing countries.

Projects like this solar desalination plant developed by MIT bring technology, energy, and water to underprivileged areas. This is also the raison d’être of the Acciona Foundation, which carries out projects to take water or clean energy to unreached areas, such as Oaxaca or the tropical forests of Peru. Undoubtedly, energy technology and infrastructure advances are one of the keys to developing these areas.

A new age of additive manufacturing electronics

We have already seen that 3D printing has a wide range of applications, including metals and biomaterials. In recent years, the shortage of microchips due to problems in logistic chains caused by the pandemic and war conflicts has been a constant. And here, 3D printing could also play a crucial role.

Additive manufacturing electronics (AME) enable 3D printing to produce semiconductors, sensors, transistors, and other computer components, wearables, and circuitries.

A concrete example in this field is a project at the University of Washington, which has created a thermoelectric device that converts body heat into electricity. They have used a 3D printing system that generates different layers with specific functionalities to achieve this.

Thus, a liquid metal alloy filler is used that gives the wearable conductivity while simultaneously allowing it to stretch. The device also contains microspheres that transmit heat to the semiconductors in the base layer. According to the researchers, this type of wearable can be printed on textiles and curved surfaces.

Additive manufacturing electronics is a technique with great potential. So much so that some studies suggest it could quadruple in value over this decade, reaching almost $40 billion by 2030.

Source: